- Startpagina

- 3D Printers and accessoires

- Modelleren

- Afvormen & Gieten

- Tin Siliconen

- Platinum Siliconen

- Dragon Skin™ Serie

- Ecoflex™ Serie

- Equinox™ Serie

- Mold Star™ Serie

- Rebound™ Serie

- Smooth-Sil™ Serie

- SORTA-Clear™ Serie

- Body Double™ Siliconen

- Psycho Paint™

- PlatSil® Gel & Deadener

- Rubber Glass®

- Encapso™ K

- Solaris™

- Soma Foama™ Silicone Schuim

- EZ-Brush™ Vac Bag Siliconen

- EZ-Spray™ Siliconen

- Silicone Additieven

- PU-rubbers

- Alginaat

- PU-harsen

- PU Schuim

- Epoxies

- Polyester

- Latex, Schuimlatex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica

- Monster Makers Schuimlatex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's HX-200™ Coating/Dipping Latex

- Holden's HX-Body Latex™ - Kwastbaar

- Holden's Mold Making Latex HX-80™

- Holden's Mold Making Latex High Viscosity HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's Cosmetic Latex™

- Holden's HX-Frisket Masking Latex™

- Holden's HX-Injection Medium™

- Latex Accessoires

- Latex Pigmenten

- Latex Verf

- Latex Thickener

- AcrylCast

- Prince August

- Gips, Gipsverband & Cement

- Jesmonite Acryl Systeem

- Buddy Rhodes Beton Systeem

- Verzegelaars & Losmiddel

- Additieven

- Pigment

- Jesmonite Pigmenten

- Pure Pigments

- Ultra Fine Pigments

- Silc Pig™ Pigmenten

- Glow Worm Pigmenten

- Cryptolyte

- Silc Pig™ Electric

- SilTone

- SilTone Kits

- Silicone Pigments - FuseFX Coloring System

- Silicone Coloring System S.A.M

- Key-Pigments Silicone Pigments

- Flock vezels

- Latex Pigments

- Polyester Pigment

- UVO Pigmenten - UV bestendig

- SO-Strong kleurstoffen

- Ignite

- Real Metal Powders

- Faux Metal Powders

- CastMagic Powders

- Verf

- Maker Pro Paint™

- Maker Pro Paint™ Fluorescent

- Maker Pro Paint Additive

- Vallejo acryl verf

- Maker Pro Paint™ Metallics

- Vallejo Metal Color

- Vallejo Acrylic Mud

- Vallejo Primers and Laquer

- Psycho Paint™

- Latex-verf

- Latex Paint Base

- Fuse-FX LY-series paints

- FuseFX M-series paints

- Fuse-FX F-series paint

- Jesmonite verf

- Vulmiddelen & Afwerking

- Oplosmiddelen & Verdunners

- Lijmen

- Gereedschap

- Apparatuur

- Speciale Make-Up

- Skin Illustrator Palettes

- Skin Illustrator Liquids

- Fleshstone 60ml

- Fleshstone 120ml

- Dark Fleshstone 60ml

- Dark Fleshstone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras 60ml

- Mardi Gras 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Singles

- Skin Illustrator Glazing Spray

- Skin Illustrator Glazing Gels

- Skin Illustrator Concentrates

- Skin Illustrator Mouth FX

- RipperFX Palettes

- Allied FX (Blue Bird)

- Stacolor Paletten

- MaqPro Farde Palettes

- MaqPro Make-Up Mixer

- MaqPro Creamy

- MaqPro Bruise Gel

- TS PAX Paints

- Rubber Mask Grease Paint

- Old Age Stipple

- Tattoo Sheets

- Kwasten Make-Up

- Stempels & Mallen

- Sponges and Applicators

- Head Armatures

- FormX Tools

- Kryolan Make-Up

- Special Effects

- Prothetische Materialen

- FormX Academy

- Toepassingen

- Literatuur

VytaFlex™ serie

De VytaFlex™ serie is de nieuwste ontwikkeling in Smooth-On's bekende lijn PU-rubbers. Met een 1A:1B mengverhouding bieden zij hetzelfde gebruiksgemak maar leveren zij nog meer sterkte, duurzaamheid en prestatie. De VytaFlex™ rubbers werken vooral goed met gepigmenteerd beton of gips. Doordat zij geen kleurstofstof uit het beton absorberen dragen zij bij kleurwisseling geen kleurresten over naar het volgende gietsel. VytaFlex™ mallen zullen keer op keer detail- en kleurgetrouwe gietsels leveren.

De VytaFlex™ rubbers zijn verkrijgbaar in hardheden shore A10, A20, A30, A40, A45, A50 en shore A60.

VytaFlex™ 20 is transparant en vrijwel kleurloos en wordt daarom veel gebruikt voor decoratieve- en special-effect toepassingen.

Technisch bulletin

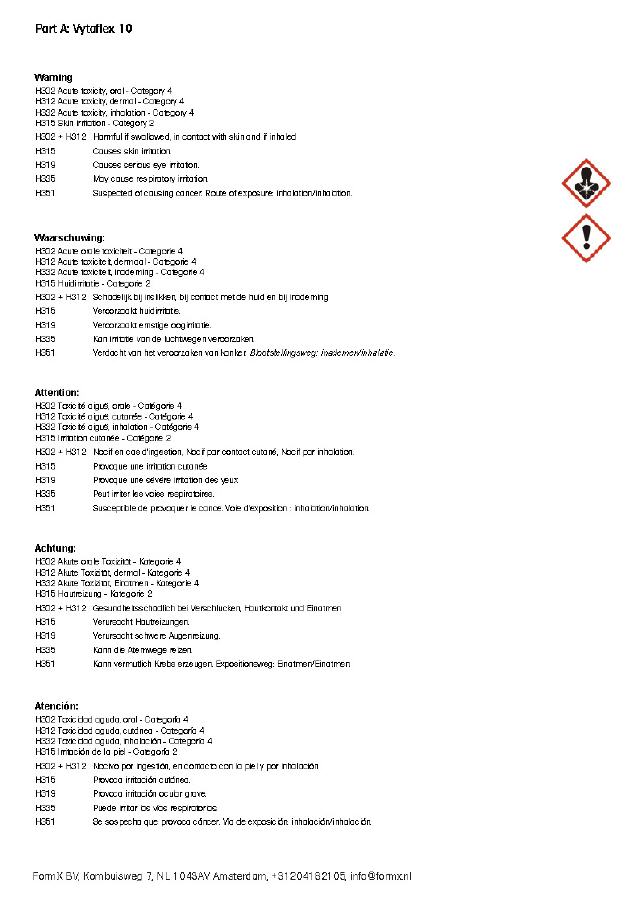

Vytaflex 10 Veiligheidsinformatie

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Read the safety information label. Click on the image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

- Lisez les informations de sécurité cliquez sur l'image

VytaFlex™ 10 producten

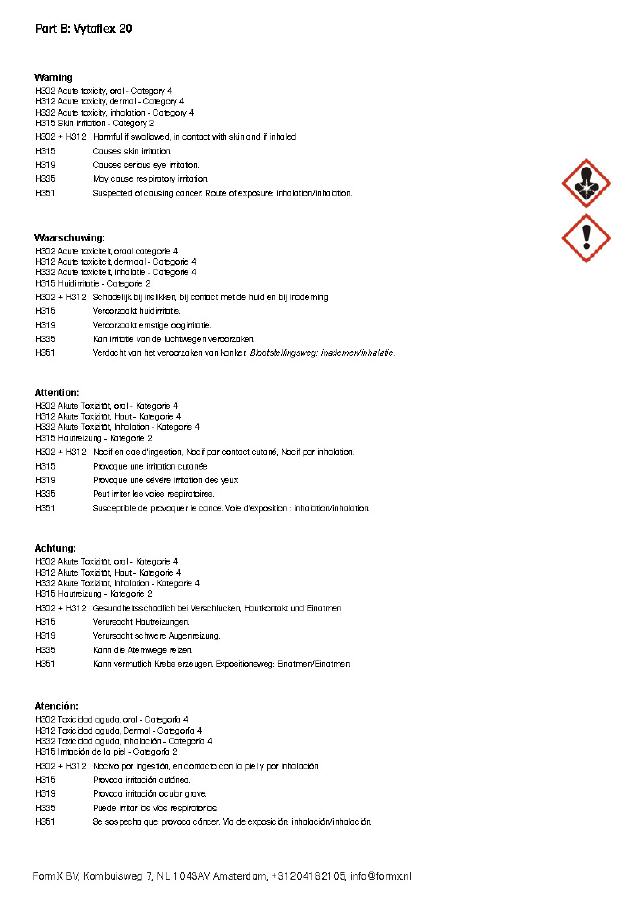

Vytaflex 20 Veiligheidsinformatie

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Read the safety information label. Click on the image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

- Lisez les informations de sécurité cliquez sur l'image

VytaFlex™ 20 producten

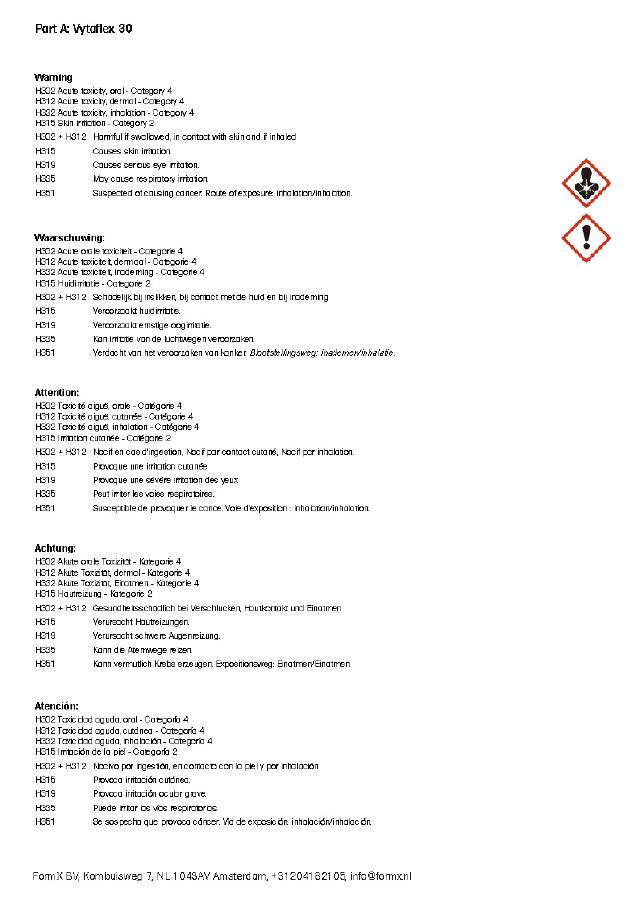

Vytaflex 30 Veiligheidsinformatie

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Read the safety information label. Click on the image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

- Lisez les informations de sécurité cliquez sur l'image

VytaFlex™ 30 producten

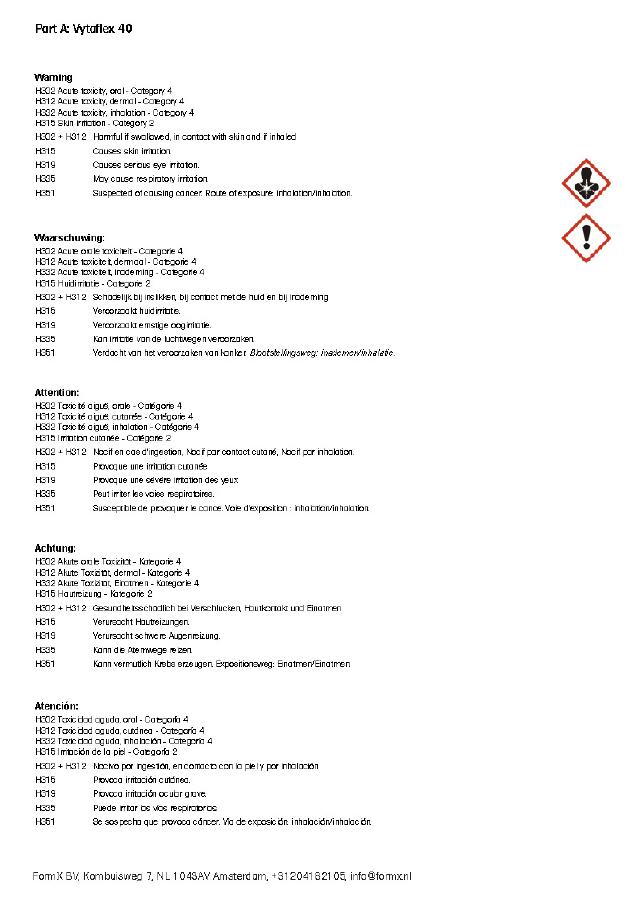

Vytaflex 40 Veiligheidsinformatie

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Read the safety information label. Click on the image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

- Lisez les informations de sécurité cliquez sur l'image

VytaFlex™ 40 producten

Vytaflex 45 Veiligheidsinformatie

VytaFlex™ 45 products

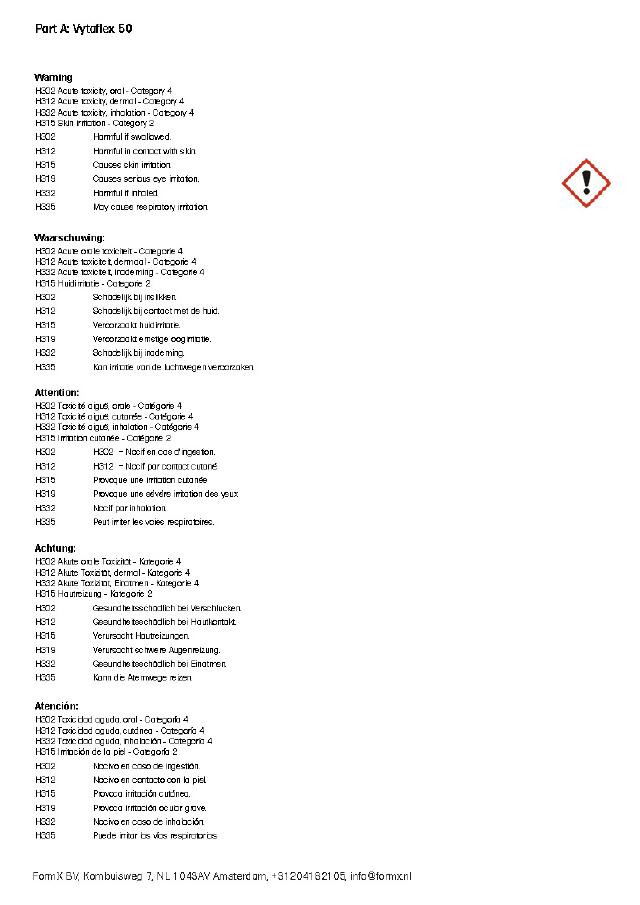

Vytaflex 50 Veiligheidsinformatie

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Read the safety information label. Click on the image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

- Lisez les informations de sécurité cliquez sur l'image

VytaFlex™ 50 producten

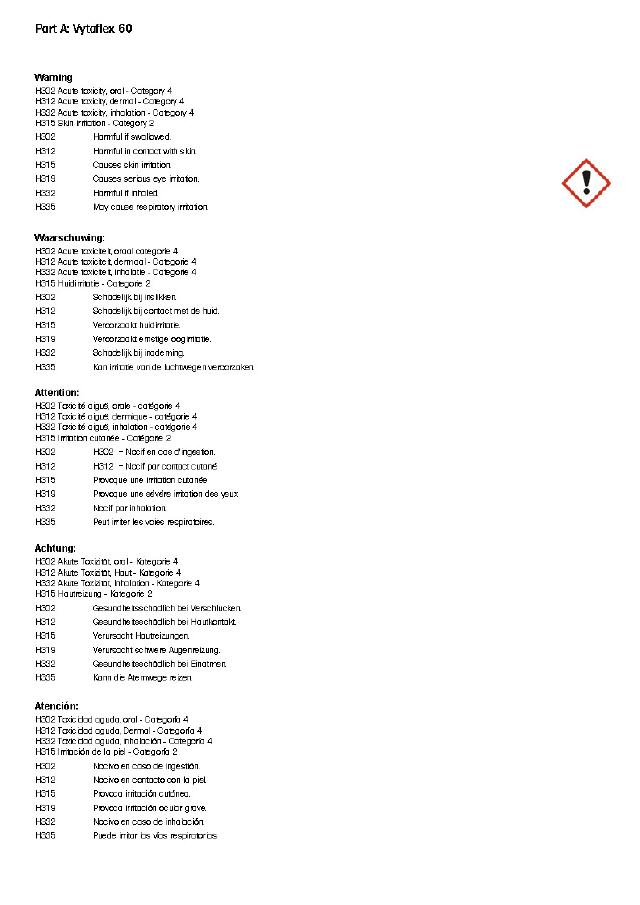

Vytaflex 60 Veiligheidsinformatie

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Read the safety information label. Click on the image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

- Lisez les informations de sécurité cliquez sur l'image

VytaFlex™ 60 producten

Preparation - Store and use at room temperature (23°C). These products have a limited shelf life and should be used as soon as possible. Environmental humidity should be as low as possible. Good ventilation (room size) is essential. Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk.

Some Materials Must Be Sealed - Urethanes are adhesive. To prevent adhesion between the rubber and model surface, models made of porous materials (gypsum plasters, concrete, wood, stone, etc.) must be sealed prior to applying a release agent. SuperSeal® (available from Smooth-On) or One Step® are fast drying sealers suitable for sealing porous surfaces without interfering with surface detail. Sonite Wax®or high-grade shellac is suitable for rough contours. A high quality Shellac is suitable for sealing modeling clays that contain sulfur or moisture (water based). Thermoplastics (polystyrene) must also be sealed with shellac or PVA. In all cases, the sealing agent should be applied and allowed to completely dry prior to applying a release agent.

Non-Porous Surfaces - Metal, glass, hard plastics, sulfur free clays, etc. require only a release agent.

IMPORTANT: Shelf life of product is reduced after opening. Remaining product should be used as soon as possible. Immediately replacing the lids on both containers after dispensing product will help prolong the shelf life of the unused product. XTEND-IT® Dry Gas Blanket (available from Smooth-On) will significantly prolong the shelf life of unused liquid urethane products.

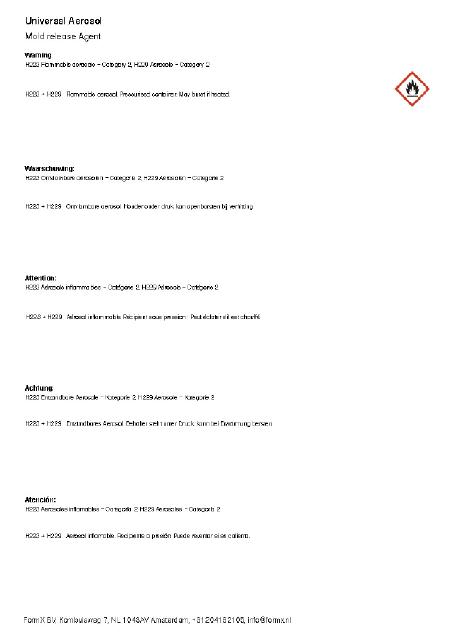

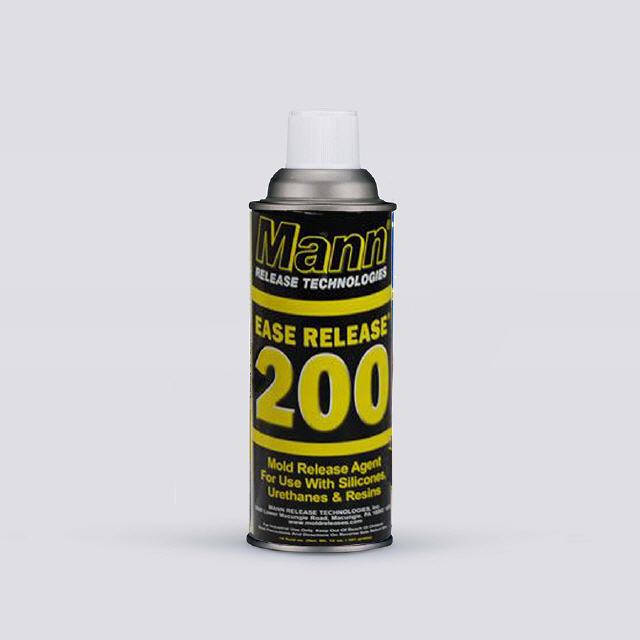

Applying A Release Agent - A release agent is necessary to facilitate demolding when casting into or over most surfaces. Use a release agent made specifically for mold making (Universal® Mold Release available from Smooth-On). A liberal coat of release agent should be applied onto all surfaces that will contact the rubber.

IMPORTANT: To ensure thorough coverage, lightly brush the release agent with a soft brush over all surfaces of the model. Follow with a light mist coating and let the release agent dry for 30 minutes. Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

MEASURING & MIXING - Liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal or plastic. Materials should be stored and used in a warm environment 23°C.

IMPORTANT: Pre Mix the Part B before using. After dispensing equal amounts of Parts A and B into mixing container, mix thoroughly for at least 3 minutes making sure that you scrape the sides and bottom of the mixing container several times.

If Mixing Large Quantities (7 kgs. or more) at one time, use a mechanical mixer (i.e. Squirrel Mixer or equal) for 3 minutes followed by careful hand mixing for one minute as directed above. Then, pour entire quantity into a new, clean mixing container and do it all over again.

Although this product is formulated to minimize air bubbles in your the cured rubber, vacuum degassing prior to pouring rubber will further reduce entrapped air.

POURING, CURING & PERFORMANCE - For best results, pour your mixture in a single spot at the lowest point of the containment field. Let the rubber seek its level up and over the model. A uniform flow will help minimize entrapped air. The liquid rubber should level off at least 1.3 cm over the highest point of the model surface.

Curing - Allow rubber to cure a minimum of 16 – 24 hours at room temperature (23°C) before demolding. VytaFlex® 10 should cure for at least 24 hours before demolding. Cure time can be reduced with mild heat or by adding Smooth-On “KickIt®” Cure Accelerator. Do not cure rubber where temperature is less than 18°C.

Post Curing - Optional . . . Following an overnight cure, heating the rubber to 65°C for 4 to 8 hours will increase physical properties and performance.

Using The Mold - If using as a mold material, a release agent should be applied to the mold before each casting. In & Out® II Concrete Release Concentrate (available from Smooth-On) is recommended for releasing concrete.

Performance & Storage - Fully cured rubber is tough, durable and will perform if properly used and stored. The physical life of the rubber depends on how you use it.

| VytaFlex™ | Mengverhouding (Volume) | Gemengde Viscociteit (mPas) | Specifiek Gewicht (g/cm⊃3;) | Verwerktijd (min) | Uithardtijd (uur) | Kleur | Hardheid (Shore A) | Treksterkte (psi) | Rek bij Breuk (%) | Krimp (%) |

| 10 | 1A:1B | 3100 | 1,00 | 30 | 24 | Créme | 10 | 200 | 1000 | <0,1 |

| 20 | 1A:1B | 1000 | 1,00 | 30 | 16 | Helder Amber | 20 | 200 | 1000 | <0,1 |

| 30 | 1A:1B | 1800 | 1,02 | 30 | 16 | Créme | 30 | 500 | 1000 | <0,1 |

| 40 | 1A:1B | 2000 | 1,03 | 30 | 16 | Créme | 40 | 522 | 660 | <0,1 |

| 45 | 1A:1B | 2000 | 1,04 | 30 | 16 | Créme | 45 | 886 | 900 | <0,1 |

| 50 | 1A:1B | 2000 | 1,04 | 60 | 16 | Créme | 50 | 588 | 400 | <0,1 |

| 60 | 1A:1B | 2000 | 1,04 | 60 | 16 | Créme | 60 | 880 | 480 | <0,1 |

Benodigdheden

- Mengbekers

- Maatcylinders & bekers

- Weegapparatuur

- Kwasten

- Veiligheidsmaterialen

- Losmiddellen

Mengen, Meten & Wegen

Losmiddelen

Bescherming

Kwasten

Hier vindt u onze produkten gerangschikt naar diverse toepassingsmogelijkheden, zoals: Lifecasting, boetseren, afvormen, gieten, make-up, stuntwerk, dentaalwerk en studie.