- Startpagina

- 3D Printers and accessoires

- Modelleren

- Afvormen & Gieten

- Tin Siliconen

- Platinum Siliconen

- Dragon Skin™ Serie

- Ecoflex™ Serie

- Equinox™ Serie

- Mold Star™ Serie

- Rebound™ Serie

- Smooth-Sil™ Serie

- SORTA-Clear™ Serie

- Body Double™ Siliconen

- Psycho Paint™

- PlatSil® Gel & Deadener

- Rubber Glass®

- Encapso™ K

- Solaris™

- Soma Foama™ Silicone Schuim

- EZ-Brush™ Vac Bag Siliconen

- EZ-Spray™ Siliconen

- Silicone Additieven

- PU-rubbers

- Alginaat

- PU-harsen

- PU Schuim

- Epoxies

- Polyester

- Latex, Schuimlatex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica

- Monster Makers Schuimlatex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's HX-200™ Coating/Dipping Latex

- Holden's HX-Body Latex™ - Kwastbaar

- Holden's Mold Making Latex HX-80™

- Holden's Mold Making Latex High Viscosity HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's Cosmetic Latex™

- Holden's HX-Frisket Masking Latex™

- Holden's HX-Injection Medium™

- Latex Accessoires

- Latex Pigmenten

- Latex Verf

- Latex Thickener

- AcrylCast

- Prince August

- Gips, Gipsverband & Cement

- Jesmonite Acryl Systeem

- Buddy Rhodes Beton Systeem

- Verzegelaars & Losmiddel

- Additieven

- Pigment

- Jesmonite Pigmenten

- Pure Pigments

- Ultra Fine Pigments

- Silc Pig™ Pigmenten

- Glow Worm Pigmenten

- Cryptolyte

- Silc Pig™ Electric

- SilTone

- SilTone Kits

- Silicone Pigments - FuseFX Coloring System

- Silicone Coloring System S.A.M

- Key-Pigments Silicone Pigments

- Flock vezels

- Latex Pigments

- Polyester Pigment

- UVO Pigmenten - UV bestendig

- SO-Strong kleurstoffen

- Ignite

- Real Metal Powders

- Faux Metal Powders

- CastMagic Powders

- Verf

- Maker Pro Paint™

- Maker Pro Paint™ Fluorescent

- Maker Pro Paint Additive

- Vallejo acryl verf

- Maker Pro Paint™ Metallics

- Vallejo Metal Color

- Vallejo Acrylic Mud

- Vallejo Primers and Laquer

- Psycho Paint™

- Latex-verf

- Latex Paint Base

- Fuse-FX LY-series paints

- FuseFX M-series paints

- Fuse-FX F-series paint

- Jesmonite verf

- Vulmiddelen & Afwerking

- Oplosmiddelen & Verdunners

- Lijmen

- Gereedschap

- Apparatuur

- Speciale Make-Up

- Skin Illustrator Palettes

- Skin Illustrator Liquids

- Fleshstone 60ml

- Fleshstone 120ml

- Dark Fleshstone 60ml

- Dark Fleshstone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras 60ml

- Mardi Gras 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Singles

- Skin Illustrator Glazing Spray

- Skin Illustrator Glazing Gels

- Skin Illustrator Concentrates

- Skin Illustrator Mouth FX

- RipperFX Palettes

- Allied FX (Blue Bird)

- Stacolor Paletten

- MaqPro Farde Palettes

- MaqPro Make-Up Mixer

- MaqPro Creamy

- MaqPro Bruise Gel

- TS PAX Paints

- Rubber Mask Grease Paint

- Old Age Stipple

- Tattoo Sheets

- Kwasten Make-Up

- Stempels & Mallen

- Sponges and Applicators

- Head Armatures

- FormX Tools

- Kryolan Make-Up

- Special Effects

- Prothetische Materialen

- FormX Academy

- Toepassingen

- Literatuur

Real Metal Powders

Metal Powders

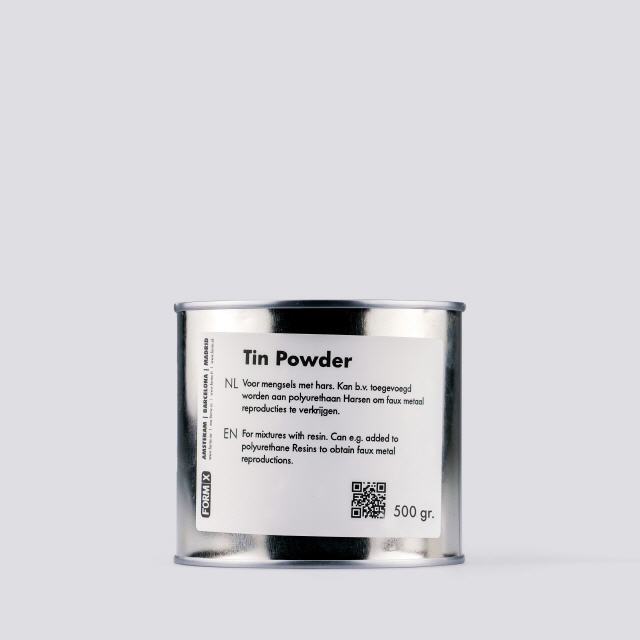

Metal powders are used, as an additive to various resins and acrylcast to make castings with a metallic appearance, the so-called "cold-cast metal".

"Cold-Casting" is a term used to describe the process of mixing metal powder with a resin and applying the mixture into a mold. The finished casting gives the appearance and weight of solid metal. The metal cold-cast process is faster and much less expensive when compared with foundry casting of molten metal. To make a metal cold-casting, metal powder is mixed into Colormatch® resin until the mixture is thick and creamy. The mixture is then "slush-cast" or brushed onto the mold surface until the resin cures. The gel coat is then back-filled with straight resin, resin mixed with metal powder, resin mixed with lead shot or Foam-iT! rigid foam.

FormX offers metal powders that can be added to our liquid plastics to create cold cast metal castings.

Powders include bronze, brass, copper, aluminum, ickel/silver (for a pewter-like effect), Copper, White Bronze and Stainless Steel.

Real Metal Powders

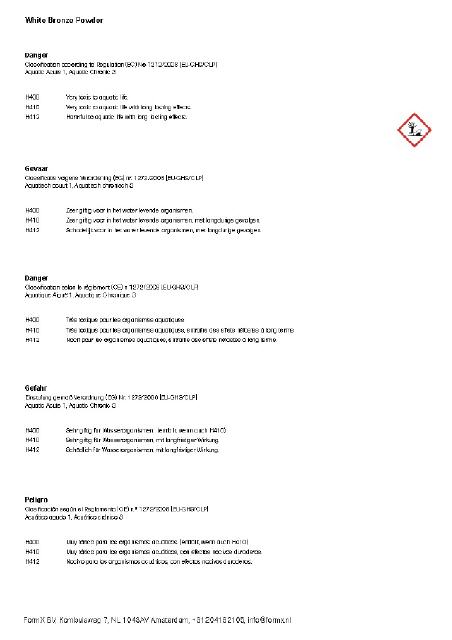

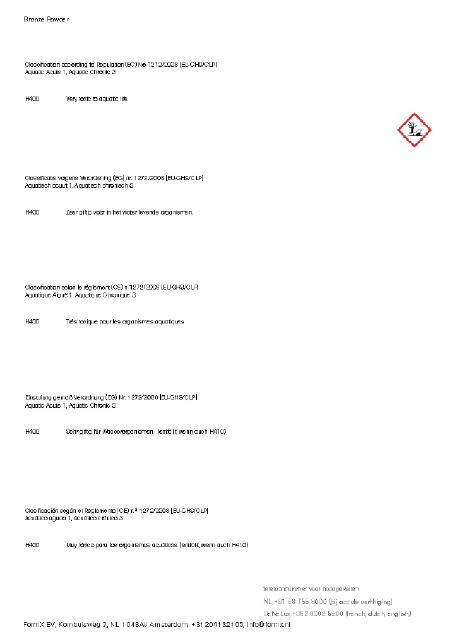

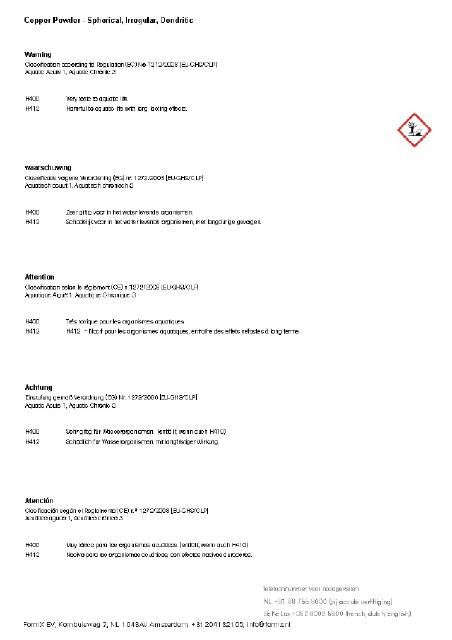

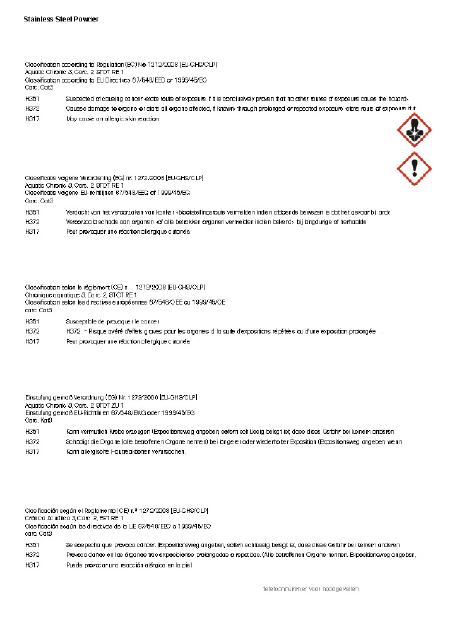

Real Metal Powders Safety

kieswijzer

Hier vindt u onze produkten gerangschikt naar diverse toepassingsmogelijkheden, zoals: Lifecasting, boetseren, afvormen, gieten, make-up, stuntwerk, dentaalwerk en studie.