- Startpagina

- 3D Printers and accessoires

- Modelleren

- Afvormen & Gieten

- Tin Siliconen

- Platinum Siliconen

- Dragon Skin™ Serie

- Ecoflex™ Serie

- Equinox™ Serie

- Mold Star™ Serie

- Rebound™ Serie

- Smooth-Sil™ Serie

- SORTA-Clear™ Serie

- Body Double™ Siliconen

- Psycho Paint™

- PlatSil® Gel & Deadener

- Rubber Glass®

- Encapso™ K

- Solaris™

- Soma Foama™ Silicone Schuim

- EZ-Brush™ Vac Bag Siliconen

- EZ-Spray™ Siliconen

- Silicone Additieven

- PU-rubbers

- Alginaat

- PU-harsen

- PU Schuim

- Epoxies

- Polyester

- Latex, Schuimlatex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica

- Monster Makers Schuimlatex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's HX-200™ Coating/Dipping Latex

- Holden's HX-Body Latex™ - Kwastbaar

- Holden's Mold Making Latex HX-80™

- Holden's Mold Making Latex High Viscosity HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's Cosmetic Latex™

- Holden's HX-Frisket Masking Latex™

- Holden's HX-Injection Medium™

- Latex Accessoires

- Latex Pigmenten

- Latex Verf

- Latex Thickener

- AcrylCast

- Prince August

- Gips, Gipsverband & Cement

- Jesmonite Acryl Systeem

- Buddy Rhodes Beton Systeem

- Verzegelaars & Losmiddel

- Additieven

- Pigment

- Jesmonite Pigmenten

- Pure Pigments

- Ultra Fine Pigments

- Silc Pig™ Pigmenten

- Glow Worm Pigmenten

- Cryptolyte

- Silc Pig™ Electric

- SilTone

- SilTone Kits

- Silicone Pigments - FuseFX Coloring System

- Silicone Coloring System S.A.M

- Key-Pigments Silicone Pigments

- Flock vezels

- Latex Pigments

- Polyester Pigment

- UVO Pigmenten - UV bestendig

- SO-Strong kleurstoffen

- Ignite

- Real Metal Powders

- Faux Metal Powders

- CastMagic Powders

- Verf

- Maker Pro Paint™

- Maker Pro Paint™ Fluorescent

- Maker Pro Paint Additive

- Vallejo acryl verf

- Maker Pro Paint™ Metallics

- Vallejo Metal Color

- Vallejo Acrylic Mud

- Vallejo Primers and Laquer

- Psycho Paint™

- Latex-verf

- Latex Paint Base

- Fuse-FX LY-series paints

- FuseFX M-series paints

- Fuse-FX F-series paint

- Jesmonite verf

- Vulmiddelen & Afwerking

- Oplosmiddelen & Verdunners

- Lijmen

- Gereedschap

- Apparatuur

- Speciale Make-Up

- Skin Illustrator Palettes

- Skin Illustrator Liquids

- Fleshstone 60ml

- Fleshstone 120ml

- Dark Fleshstone 60ml

- Dark Fleshstone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras 60ml

- Mardi Gras 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Singles

- Skin Illustrator Glazing Spray

- Skin Illustrator Glazing Gels

- Skin Illustrator Concentrates

- Skin Illustrator Mouth FX

- RipperFX Palettes

- Allied FX (Blue Bird)

- Stacolor Paletten

- MaqPro Farde Palettes

- MaqPro Make-Up Mixer

- MaqPro Creamy

- MaqPro Bruise Gel

- TS PAX Paints

- Rubber Mask Grease Paint

- Old Age Stipple

- Tattoo Sheets

- Kwasten Make-Up

- Stempels & Mallen

- Sponges and Applicators

- Head Armatures

- FormX Tools

- Kryolan Make-Up

- Special Effects

- Prothetische Materialen

- FormX Academy

- Toepassingen

- Literatuur

SuperSeal®

SuperSeal® is ontwikkeld als een economisch, sneldrogend afdichtingsmiddel voor diverse poreuze oppervlakken, waaronder gipspleisters, beton en hout. Dit afdichtingsmiddel dicht oppervlakken snel en doeltreffend af zonder de oppervlakte details te verstoren. De nieuwe formule biedt betere prestaties en snellere verdamping. Vervolgens kan gietrubber (polyurethaan, silicone of polysulfide) worden aangebracht.

Eigenschappen

Lage kosten

Lage viscositeit - maakt goed nat over elk oppervlak

Verdampt snel

Ultradunne film - verstoort de reproductie van de details of afwerking van het oppervlak niet.

Geeft uitgehard rubber mal oppervlak een gladde, satijnen afwerking

Verwijderbaar - kan van het model oppervlak worden afgespoeld met warm water

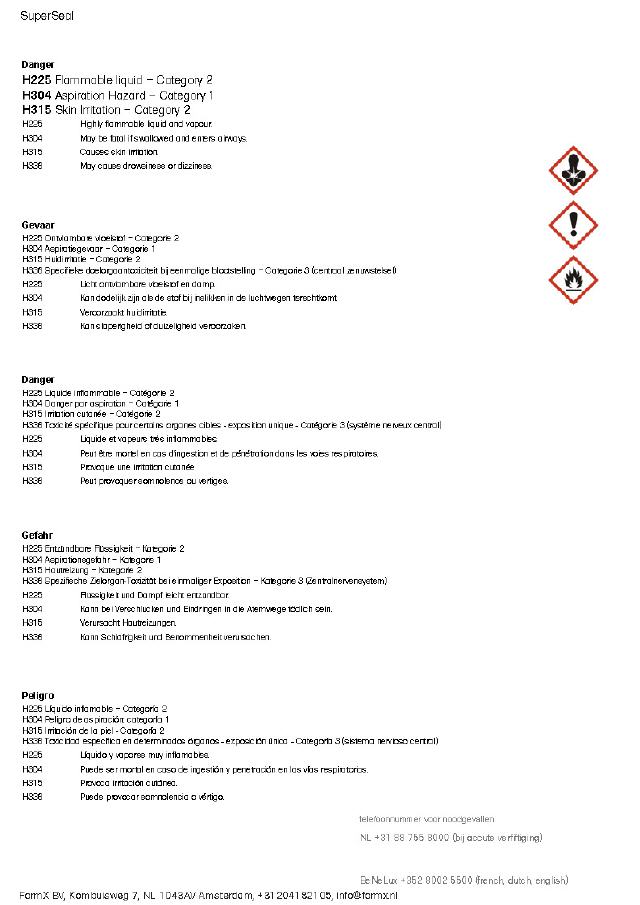

SuperSeal Veiligheidsinformatie

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

- Read the safety information label. Click on the image

- Lisez les informations de sécurité cliquez sur l'image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

SuperSeal

Safety - CONTENTS FLAMMABLE: Keep product away from flame and all ignition sources. Use in a properly ventilated area (“room size” ventilation). Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk.

Store and use material at room temperature (23°C). This product has a limited shelf life and should be used as soon as possible.

NOTE: ALWAYS SHAKE WELL BEFORE USING

A minimum of 2 coats of SuperSeal® is recommended to seal most surfaces. For extremely porous surfaces (i.e. limestone or dry plaster) an additional coat of SuperSeal® may be required. Or apply two coats of SuperSeal® and follow with an application of Ease Release® 200. Superseal® can be applied using a soft brush or a non-aerosol spray bottle to lightly mist SuperSeal® onto model.

Apply a thorough thin coating of SuperSeal® over entire model surface and surrounding forms including intricate detail and undercuts. Compressed air or a hair dryer may be used to blow off any excess that has pooled. Let dry for 5 minutes.

Repeat above 1 - 2 more times and let final coat dry for at least 1 hour.

If recommended by mold rubber manufacturer, apply a light mist coating of release agent (i.e. Ease Release® 200). Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Important: Discoloration of model surface may occur. If compatibility between SuperSeal® and model surface or SuperSeal® and a particular mold rubber is a concern, a small-scale test should be made on an identical surface prior to use.

Transport Regulated Goods

The transport of items out of this group can be restricted due to EU restrictions and regulations and will require a specialized carrier. Transport costs will not be automatically calculated. We will give you transport options and a quote later. Preparing this order for transport will not fit within our normal time frame and delivery may take a few days longer.

GUIDE

Let us help you find your way.

The list below may help you find what you are looking for via an alternative path.